You are here

Back to topWhat is transient response?

An ideal power converter needs to maintain a stable output voltage, no matter how the load changes. However, in applications, the output load step will affect the output voltage. For example, the amount of change of the output voltage measured for different loads in the steady-state is the load regulation. When the load changes in a transient state, it is necessary to consider the overshoot, undershoot, and the recovery time of the output voltage. These three indicators all rely on the compensation system of the converter. This article will introduce the occurrence process of transient response and the factors that affect the transient response and observe the changes in output voltage under different conditions through actual waveform measurement, and provide suggestions for improvement.

1. Transient response

When the load changes instantly, the output voltage will produce a reaction. In other words, the process of returning to the set value after the output voltage rises or falls, which is called the transient response.

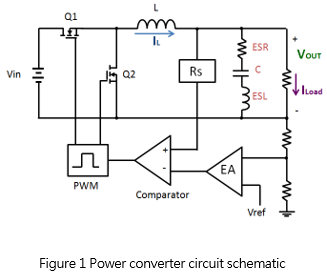

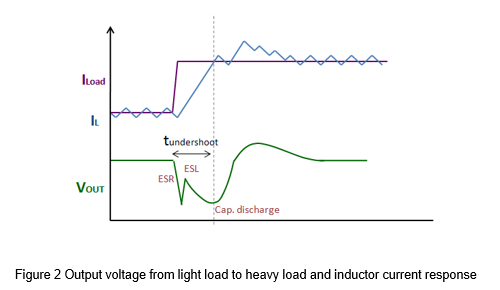

The following is the power converter is used to analyze how the transient response occurs. Figure 1 is a schematic circuit diagram of the power converter. And figure 2 shows the process that when the load current from light to heavy, output voltage and inductor current react at the same time. Under the current changes, the capacitance cannot be regarded as an ideal capacitor, so parasitic elements must be considered, including equivalent series resistance (ESR) and equivalent series inductance (ESL).

When the load step and the output current increase instantly, the converter cannot respond to provide enough current immediately. So the output capacitor discharges to make up for the lack of output current, and the ESR and ESL of the output capacitor will make the voltage across the output capacitor drop. ESR causes a voltage drop and is positively correlated with the degree of load change. ESL reduces the voltage on both sides of the output capacitor and generates spikes. According to the characteristics of the inductance, the spikes generated by ESL are related to the load transient time. If the faster the load rises, the bigger the voltage spikes generate.

When the voltage drop is detected by the error amplifier, the feedback system will increase the voltage of the compensator and increase the turn-on time of switch Q1. So that the inductor current rises to meet the increased load current, and the capacitor starts charging. The output voltage tends to stable.

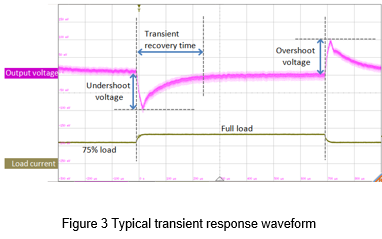

The transient response test can understand the stability of the converter's output voltage. The specifications of the power converter usually have defined the transient response time and the tolerance of output voltage. It must note during the measurement that the load transient time should much shorter than the transient recovery time, and the period of the load transient must be greater than the recovery time of the converter, otherwise the stability problem cannot be displayed on the waveform.

The following figure shows a typical transient response waveform. In this case, the output is 12VDC, the load is from 75% to 100% to 75%, the maximum voltage change is 100mV, which is equivalent to 0.8% of output voltage, and the recovery time is 250ms. The process of voltage transient recovery is a smooth curve, showing stable circuit characteristics.

2. The factors affect the transient response

In the general control system, several factors affect the performance of transient response. First of all, the components used in the entire loop, such as optical coupling, diodes, and transformers, have delay time. It means that when the load changes, the converter will start reaction after the minimum delay time. This minimum delay time does not represent the transient response time, but only a small part of it.

The main factors that affect the transient response like the compensation level of the internal error amplifier. The error amplifier is used to adjust the PWM (Pulse Width Modulation), and the PWM modulates the on-time of the transistor to respond to the change in the output voltage. And the bandwidth of the control loop will affect the speed of adjustment. When the bandwidth is larger, the load transient can adjust more quickly.

Two factors affect the transient response in external conditions. One is the output capacitance. If the capacitance is large, the undershoot or overshoot of the output voltage can reduce, but the recovery time will increase. The second is the magnitude of change and rate of change of the load current. When the load current rises or falls slowly, the peak value of the output voltage is small. In addition, when the magnitude of the load step increases, the output voltage will rise or fall sharply.

3. The waveform

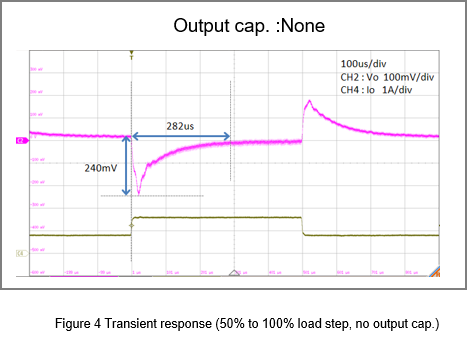

- Different of capacitance

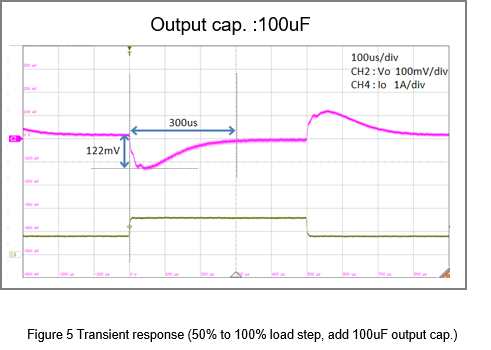

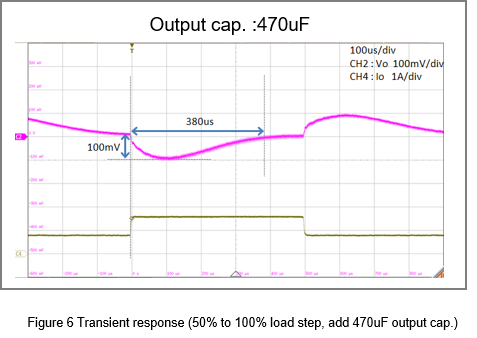

When the load step is fixed (50% to 100%load), the only change is the capacitance value of the output capacitor. It can know from the following three waveforms that the larger the capacitance is, the less variation of output voltage is, but the recovery time will increase.

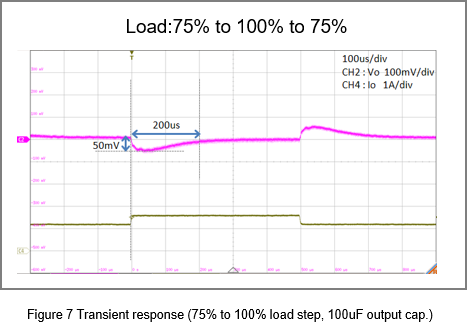

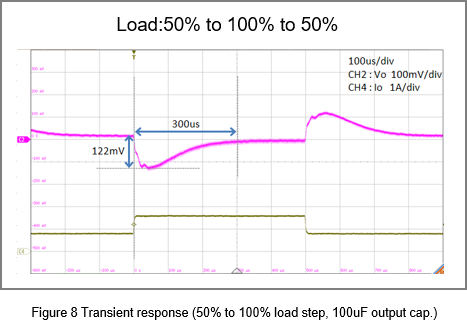

- Different magnitude of load step

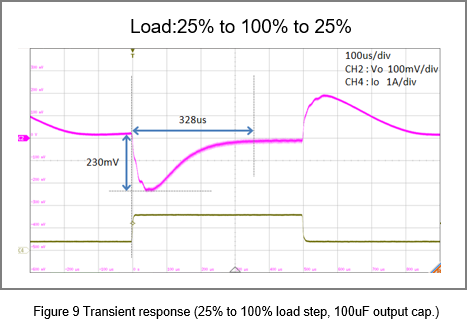

When the output capacitance is fixed (100uF), the only difference is the magnitude of load step change. When the load step is 25% load (from 75% to 100%), the undershoot of the output voltage is 50mV, and the recovery time is 200us. Then figure 8 and 9 show that the load step increase to 50% and 75% load, it make the undershoot voltage is larger, and the recovery time needs longer.

- Different rate of load change

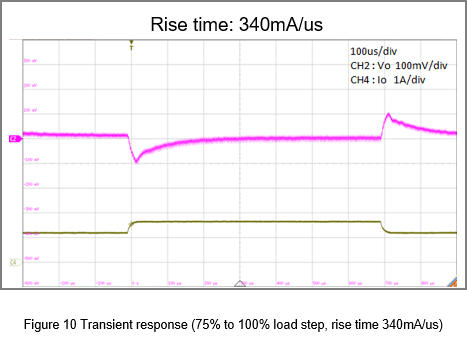

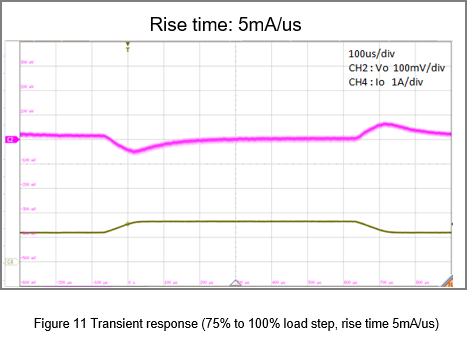

The following figures below show that the different rate of load change. The faster load current rises or falls, the larger the output voltage undershoot or overshoot is. By contrast, the slower load step results the less output voltage change.

4. Improved method

- Add output capacitor

To achieve a stable output voltage, the easiest way increased the output capacitance, but ESR and ESL still need to be considered. Ceramic capacitors have low ESR and are also a better choice in reducing voltage transients. Generally, ceramic capacitors place close to the load end of the actual application. In addition to reducing voltage transients, it also avoids oscillations in the converter's control loop. Besides, you can add an electrolytic capacitor near the output of the converter. When there is a load step, the electrolytic capacitor will react quickly in the initial stage so that the feedback circuit can respond faster, which is helpful in slow feedback response circuits.

- Layout suggestion

Under dynamic loads, the distance between the converter and the load may affect the quality of the output power. And the parasitic resistance and inductance on the path will cause an output voltage drop and result in poor load regulation. So the converter and the load need to be placed as close as possible. To reduce the effect of load transient response, generally, the output capacitance is increased to reduce the output voltage response, and the position of capacitors is most effective in the main current path.

5. Summary

With the market trend, many electronic products tend to require faster and larger current. In the selection of power converters, the products with stable output voltage are more popular. The transient response test can understand the stability of the control loop, the load regulation, the transient recovery time, and the ringing. After understanding the factors that affect the transient response, the most appropriate improvement method can find to obtain a more stable power converter.

CTC is a professional service provider for high-end power supply modules (AC to DC Converter and DC to DC Converter) for critical applications worldwide since 30 years. Our core competence is to design and deliver products with leading technologies, competitive pricing, extremely flexible lead-time, global technical service and high-quality manufacturing (Made In Taiwan).

CTC is the only corporation certificated with ISO-9001, IATF-16949, ISO22613(IRIS), and ESD/ANSI-2020. We can 100% ensure not only the product, but also our workflow and service to match quality management system for every high-end application from the very beginning. From design to manufacturing and technical support, every single detail is operated under highest standard.