You are here

Back to topPower Solutions Designed for Medical Applications

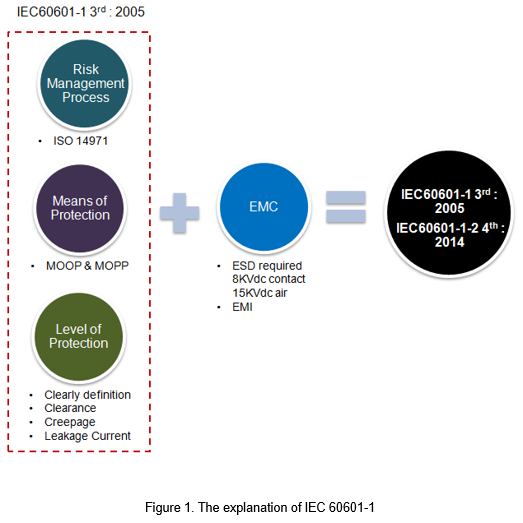

Medical equipment involves the safety of patients and operators, so the first edition of IEC 60601 was published in 1977, and this standard is adopted internationally to ensure the safety and basic performance requirements of medical electronic equipment. Because the patient may not be able to reaction normally due to anesthesia or unconsciousness, or rely on the equipment to maintain life, it is the reason why the safety specifications of medical equipment are stricter than general electrical products. In 2005, the third edition of IEC 60601-1 was updated to include risk management and classification of the potential hazards of operators and patients (MOOP & MOPP). Currently, Europe, the United States, Canada, Japan and South Korea and other regions comply with IEC 60601-1 third edition.

Nowadays, science and technology develop rapidly, the development of medical equipment has also progressed. Medical equipment is no longer used in hospitals only. There are more and more home healthcare equipments, such as blood glucose meters and heart rate monitors. In addition, due to the popularity of smart phones and tablets, these devices can communicate wirelessly through the Internet, WIFI and Bluetooth. Therefore, IEC 60601-1-2 updated the fourth edition in 2014, mainly specifying safety standards related to electromagnetic interference. Since 2019, Europe, the United States and Canada have adopted the fourth edition, so suppliers must ensure that end users in these regions will get the products meet the latest standards.

The third edition has different definitions of the risks for patients and operators. The classification of MOPP and MOOP is as follows:

- MOPP(MEANS OF PATIENT PROTECTION)

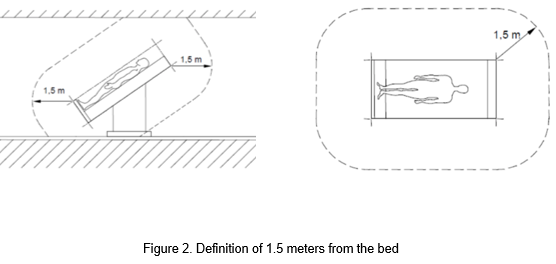

There are terminals or interfaces (RJ-45, USB, COM etc) connect to patient applied part, the diagnostic equipments connect to patient directly, or the equipments install within 1.5m of the hospital bed as the following figure.

- MOOP(MEANS OF OPERATOR PROTECTION)

The product is used only by nurses, doctors or medical technicians.

Different levels of MOOP and MOPP are achieved the ability to protect through the establishment isolation and insulation, creepage and air clearance. As shown in the table below.

| 3rd edition requirements by classification (250Vac working voltage) | ||||

| Classification | Isolation | Creepage | Air Clearance | Insulation |

| 1MOOP | 1500 Vac | 3.2 mm | 2.0mm | Basic |

| 1MOPP | 1500 Vac | 4.0 mm | 2.5mm | Basic |

| 2MOOP | 3000 Vac | 6.4 mm | 4.0mm | Double |

| 2MOPP | 4000 Vac | 8.0 mm | 5.0mm | Reinforce |

Application

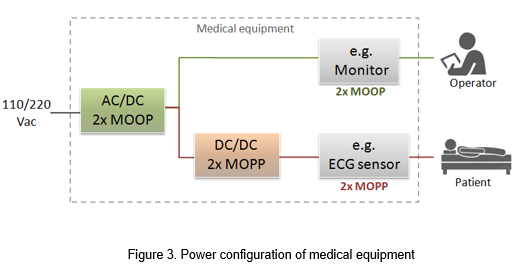

Most medical equipments need to be driven by DC power, but it must be powered by 110Vac or 220Vac. Therefore, there is an alternative solution as shown in Figure 3, using a 2xMOOP AC/DC converter and a 2xMOPP DC/DC converter, can allow the applied part with 2xMOPP, and the part that does not connect to patient can still have 2xMOOP. This configuration allows manufacturers to avoid purchasing AC/DC converters with 2xMOPP at a higher cost.

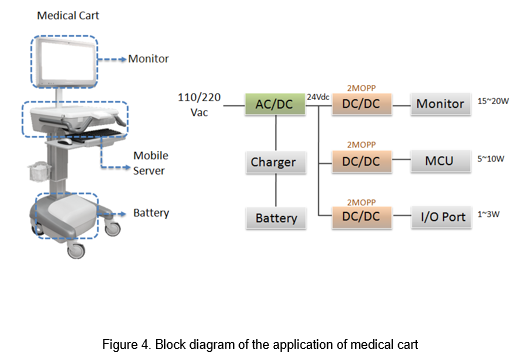

Figure 4 is a block diagram of the application of medical cart. Generally, it will be connected to the utility power or the battery, converted to DC power through the AC/DC converter, and then provided electricity to the back-end circuit through the 2xMOPP DC/DC power converter. Not only it can provide different voltages for the screen, MCU or input and output ports, but also use the DC/DC converter to make the device meet the 2xMOPP requirements.

For more information, please contact : ts@ctc-dc-dc.com

CTC is a professional service provider for high-end power supply modules (AC to DC Converter and DC to DC Converter) for critical applications worldwide since 30 years. Our core competence is to design and deliver products with leading technologies, competitive pricing, extremely flexible lead-time, global technical service and high-quality manufacturing (Made In Taiwan).

CTC is the only corporation certificated with ISO-9001, IATF-16949, ISO22613(IRIS), and ESD/ANSI-2020. We can 100% ensure not only the product, but also our workflow and service to match quality management system for every high-end application from the very beginning. From design to manufacturing and technical support, every single detail is operated under highest standard.