You are here

Back to topKey Considerations for Selecting Potting Materials in Power Converters

Power converters play a crucial role in electronic devices. Their performance and reliability directly affect the operating efficiency and lifespan of the equipment. To enhance reliability, potting and encapsulation are performed during the manufacturing of power converters to protect internal electronic components and circuit boards, achieving high durability and strong resistance to environmental interference. This article explores the various properties of potting compounds for power converters.

Introduction

Power converters are used in extreme environments such as industrial, automotive, and railway applications. Without encapsulation protection, components and circuits are exposed, which may lead to overheating or short circuits caused by the accumulation of dust or other substances.

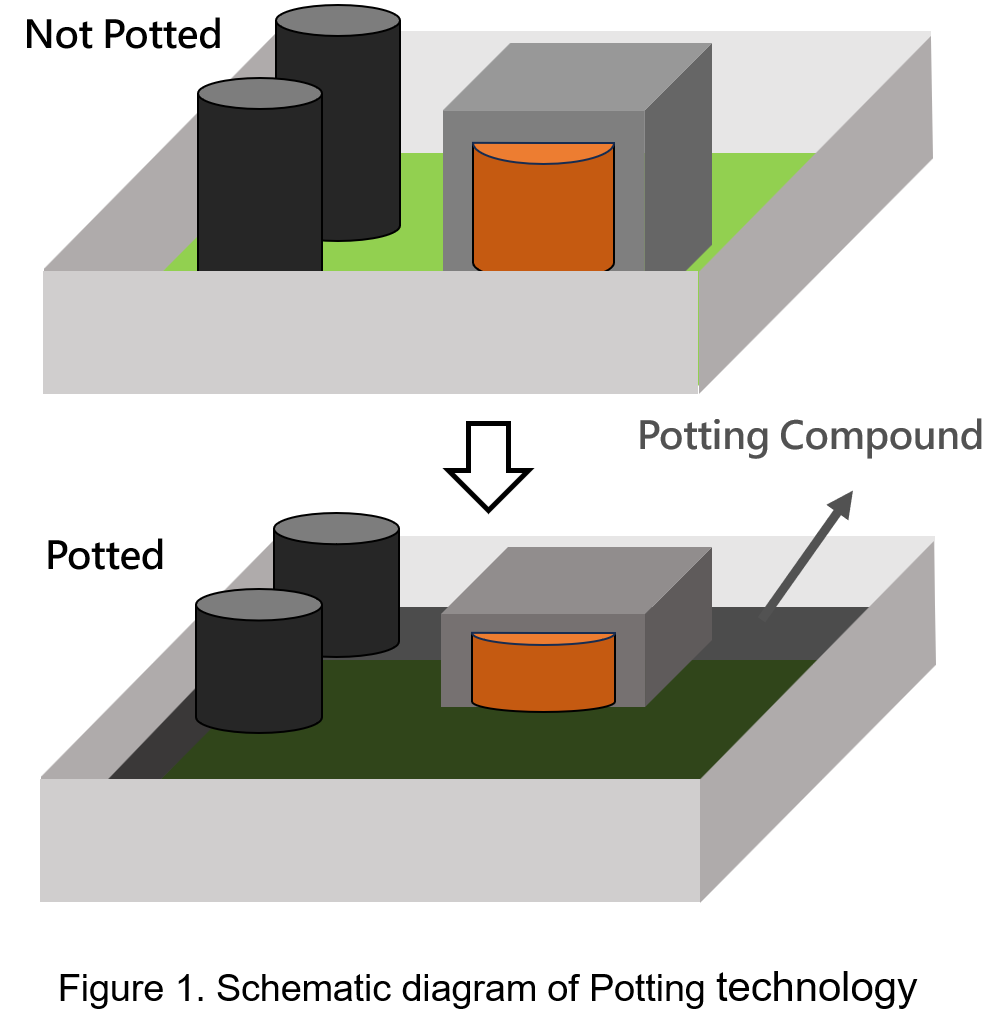

The potting process for electronic products is a technology used to protect sensitive electronic components from various environmental threats. Therefore, effective potting and encapsulation of power converters is a key step in improving their performance and reliability.

What is Potting Technology?

Potting involves filling a viscous compound into an enclosure containing electronic components. When cured under heated conditions, the material becomes a high-performance polymer. The purposes include:

- Transferring heat from the inside to the outer casing of the converter, thereby reducing internal and external thermal stress.

- Resisting physical shocks and vibrations, which helps address issues during manufacturing, assembly, and transportation of electronic products.

- Enhancing insulation between internal components and circuits to prevent over-voltage stress from causing arc discharge.

- Preventing moisture or corrosive chemicals in the air from penetrating, thus extending the converter's service life.

Potting is a critical step in the electronic assembly process. Understanding the characteristics of potting compounds—such as mechanical strength, coefficient of thermal expansion, thermal conductivity, adhesive strength, sealing performance, and corrosion protection—is essential. Therefore, analyzing potting compounds before designing power converters is necessary.

Properties of Potting Compounds

The main potting resins used in power converters include epoxy resin, silicone resin, and polyurethane. Depending on the desired properties and operating environments, each has its unique advantages and disadvantages, while all serve the purpose of potting. For power converter applications, the main requirements are improved insulation and thermal conductivity, while also ensuring operational stability and optimal protection of internal components.

The following common properties of potting compounds are discussed to help users better understand their applications:

(1) Hardness

Material hardness is a critical factor. Different applications require varying levels of hardness. Harder compounds provide better abrasion resistance and protection, while softer materials may wear more easily.

During curing, potting compounds shrink, generating internal mechanical stress on surrounding parts or creating defects and fine cracks, which allow liquids or gases to infiltrate. This internal stress is a key cause of cracks in potting compounds.

To address this, sharp corners in converter molds should be avoided in favor of rounded corners, which help evenly distribute mechanical stress. Additionally, using potting compounds with a softer hardness and some elasticity after curing, such as silicone resin, helps dissipate mechanical stress during shrinkage and maintains sealing between components.

(2) Coefficient of Thermal Expansion (CTE)

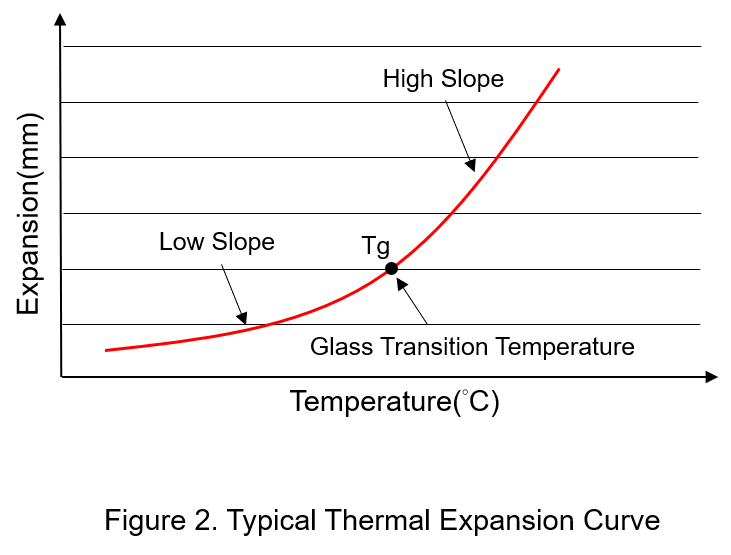

During thermal shock testing, potting materials undergo rapid contraction when exposed to cold and expansion when exposed to heat, resulting in stress due to temperature differences. If a potting material with a high Coefficient of Thermal Expansion (CTE) is selected, the excessive internal mechanical stress can easily damage sensitive components such as transformers or converter terminals.

The CTE is a physical measure of how much a potting material expands or contracts in response to temperature changes, expressed in ppm/°C. Figure 2 shows a typical curve of material expansion as temperature increases. When heated, the volume of the potting compound expands because the molecules gain more energy, increasing their movement speed and extending the material length. Conversely, when cooled, the molecular vibration amplitude decreases.

(3) Dielectric Strength

Potting technology also improves insulation by using high-insulation media like epoxy resin to replace the air around converters, thus avoiding arc discharge caused by abnormal over-voltage stress, as well as pollution from moisture and chemicals, which reduce insulation between the primary and secondary sides.

Dielectric strength is an important electrical property used to evaluate insulation, measured in volts per unit thickness. It depends on the material type, electrode shape, electric field ramp-up rate, and the surrounding dielectric environment.

Dielectric strength is defined as the maximum voltage that causes electrical breakdown in the potting material. Once breakdown occurs, the resistance drops rapidly, reducing electrical insulation. In other words, the higher the dielectric strength, the better the material resists electrical conduction.

(4) Volume Resistivity

Volume resistivity refers to a material’s ability to resist current across its cross-section and primarily depends on the material properties. It is defined as the resistance of a unit volume of cured potting compound.

Formula:

ρ : Volume resistivity, the SI unit is ohm-meter (Ohm-m)

ρ : Volume resistivity, the SI unit is ohm-meter (Ohm-m)

R: Resistance, the unit is ohm

A: The cross-sectional area of the material, the unit is m2 or cm2

L: length of potting compound, the unit is m or cm

The volume resistivity (ρ) of material is different, For example, iron is  (ohm-cm), rubber is

(ohm-cm), rubber is  (ohm-cm), glass is

(ohm-cm), glass is  ohm-cm), and polystyrene is

ohm-cm), and polystyrene is  (ohm-cm). Higher volume resistivity indicates higher insulation of the potting compounds.

(ohm-cm). Higher volume resistivity indicates higher insulation of the potting compounds.

(5) Thermal Conductivity

Thermal conductivity (K) refers to a potting compound’s ability to conduct heat. It is a key factor in power converter potting. In high-power applications, heat generated by high current must be dissipated. Excess heat reduces efficiency and may exceed temperature limits, affecting the electrical properties of adjacent components.

Potting compounds help transfer internal heat to the casing, ensuring effective heat dissipation and stable operating temperatures, thus improving durability and reliability. For high-power applications, selecting a compound with high thermal conductivity results in better cooling performance.

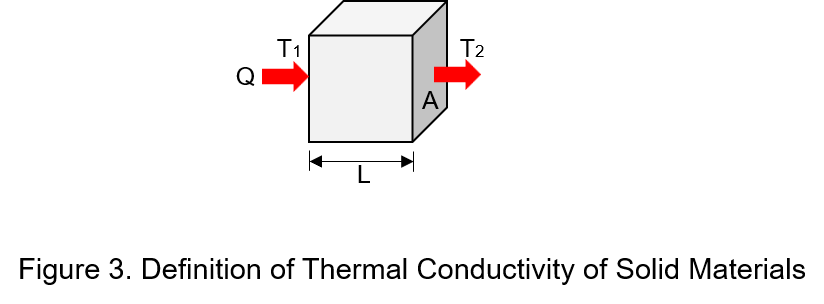

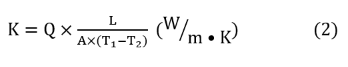

Assuming one-dimensional heat flow without lateral losses, thermal conductivity (K) is calculated as:

Heat flow direction is assumed to be straight with no lateral heat losses. The thermal conductivity(K) can be calculated using the following function:

K: thermal conductivity coefficient, the SI unit is W/m·K

Q: the amount of transferred heat, the unit is W

L: distance, the unit is m

A: Cross-sectional area of the material, the unit is m2

T1-T2 : Temperature difference between two ends, the unit is K

: Temperature difference between two ends, the unit is K

The thermal conductivity of common substances at room temperature as follow copper is 401 (W/m·K), aluminum is 240 (W/m·K), water is 0.613 (W/m·K), and rubber is 0.13 (W /m•K) and air at 0°C is 0.024 (W/m•K). The higher the thermal conductivity, the more effectively it transfers heat to another object. On the contrary, if selected lower thermal conductivity, it means the heat is less likely to dissipate.

(6) Viscosity

It requires potting compounds in most applications that are flowable and have low viscosity, so viscosity is a key criterion in potting compounds selection. It is simply defined as the fluid's resistance to flow itself, meaning the higher the viscosity, the greater the flow resistance. The main factor affecting viscosity is temperature. In most cases, viscosity decreases as temperature increases.

The viscosity of common material, such as water is 1 (cps), kerosene is 10 (cps) and engine oil is 100 (cps).

(7) Mechanical Strength

If converter pins rely only on PCB solder joints, the strength may be insufficient to resist continuous external force or support loads without cracking. Therefore, filling with potting compounds helps eliminate mechanical damage caused by shock and vibration and supports fragile components like ferrite cores. Potting offers stronger physical connections beyond solder joints.

(8) Hygroscopicity

After potting compound cured, it can directly prevent the penetration of any liquid and gas into the electronics, including water and dust, but the potting compound is mostly in a liquid state until completely curing. In the uncured state, the potting material will absorb moisture from the air.

Especially in humid environments, moisture can easily corrode the metal components and then destroy the strength, which in turn leads to the deterioration of the insulation performance. Therefore, user can use heaters and a dehumidifier to maintain ideal temperature and humidity levels.

(9) Curing Time

After potting, electronic products require sufficient time to allow the compound to cure and form a protective barrier. Curing time affects manufacturing costs, including labor. To shorten curing time, curing agents or UV exposure can be used in ventilated, warm environments.

Common reasons for incomplete curing:

- High humidity or damp tools introduce moisture into the resin

- Incorrect mixing ratio or poor stirring of the compound

- Curing conducted in environments with rapid temperature fluctuations

Conclusion

When choosing potting compounds for power converters, factors such as usage environment, performance requirements, and cost considerations should be considered. By introducing the application requirements of potting compounds and corresponding materials properties, as well as analyzing selection considerations, users can better understand different environmental conditions, including temperature, humidity, chemical substances, etc., and select materials with good insulation performance, sealing performance, high-temperature resistance, and environmental corrosion resistance to ensure the performance and reliability of electronic components.

CTC is service provider for high-end power modules (DC to DC Converter and AC to DC Converter) for critical applications worldwide since 1987. We aim to be business generator and a virtual business unit. CTC is your own team with 35 years of experience for a strong business program from market research, product definition & development, supply chain management and total technical services.

CTC is the only corporation certificated with ISO-9001, IATF-16949, ISO22613(IRIS), and ESD/ANSI-2020. We can 100% ensure not only the product, but also our workflow and service to match quality management system for every high-end application from the very beginning. From design to manufacturing and technical support, every single detail is operated under highest standard.