You are here

Back to topEMI Conducted Emission Limitations in Various Application

All power converters must pass the conducted emissions test of electromagnetic interference (EMI), and the conducted standard of EMI clearly defines the test method, limit range and immunity level. The following will introduce the precautions for conducted emissions test and the standards of various certification agencies. For power converters used in multimedia, industrial, transportation and lighting equipment, etc.

Introduction

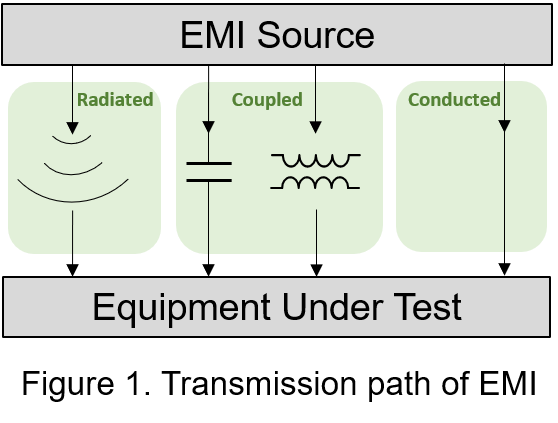

Electromagnetic Interference, also called radio-frequency interference, usually refers to the excess noise existing on the power lines, which can cause intermittent failures or even complete failure of electronic equipment. EMI is divided into two main transmission types: (1) conducted (2) radiated, and other transmission types include inductive coupling, capacitive coupling, which are shown as:

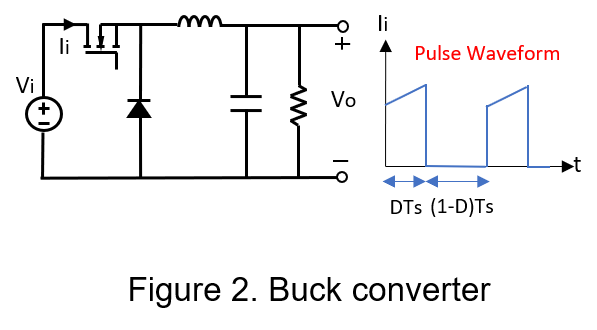

Because of the close relationship between electrical energy and magnetic energy, all currents must produce magnetic fields; and changing magnetic fields also can create currents. Hence, if the high-power power supply changes rapidly, a huge magnetic field will be caused. Conducted interference can affect the main signal when switching noise will directly contact sensitive circuits along power paths, control paths, or other physical paths. When multiple electronic equipment in a home uses the same electrical loop, turning a machine can cause the other one to malfunction. For example, when buck converter in the normal operation mode, the continuous pulse input current, means high di/dt, is easy to cause changes in the magnetic field, and also generates low-frequency noise and high-frequency noise, which mainly including the following sources of noise: power transistors, inductors and transformers, so those are the most important parts in EMI design of buck converter.

Following International standards of industrial, medical or railway application, the company uses professional instrument to test whether the EMI of each power converter passes the standards or not, so users can choose power converters that have passed international standard certification to ensure that electronic equipment can reduce the interference from electromagnetic waves.

Conducted Emission Test

Conducted emission refers to the degree of electromagnetic interference caused by part of the electromagnetic energy generated by the devices, which is transmitted back to the power supply through the power line. Since power supply path is connected to many sensitive circuits, it is very important testing the conducted emission in the laboratory and confirming that results meet the specifications

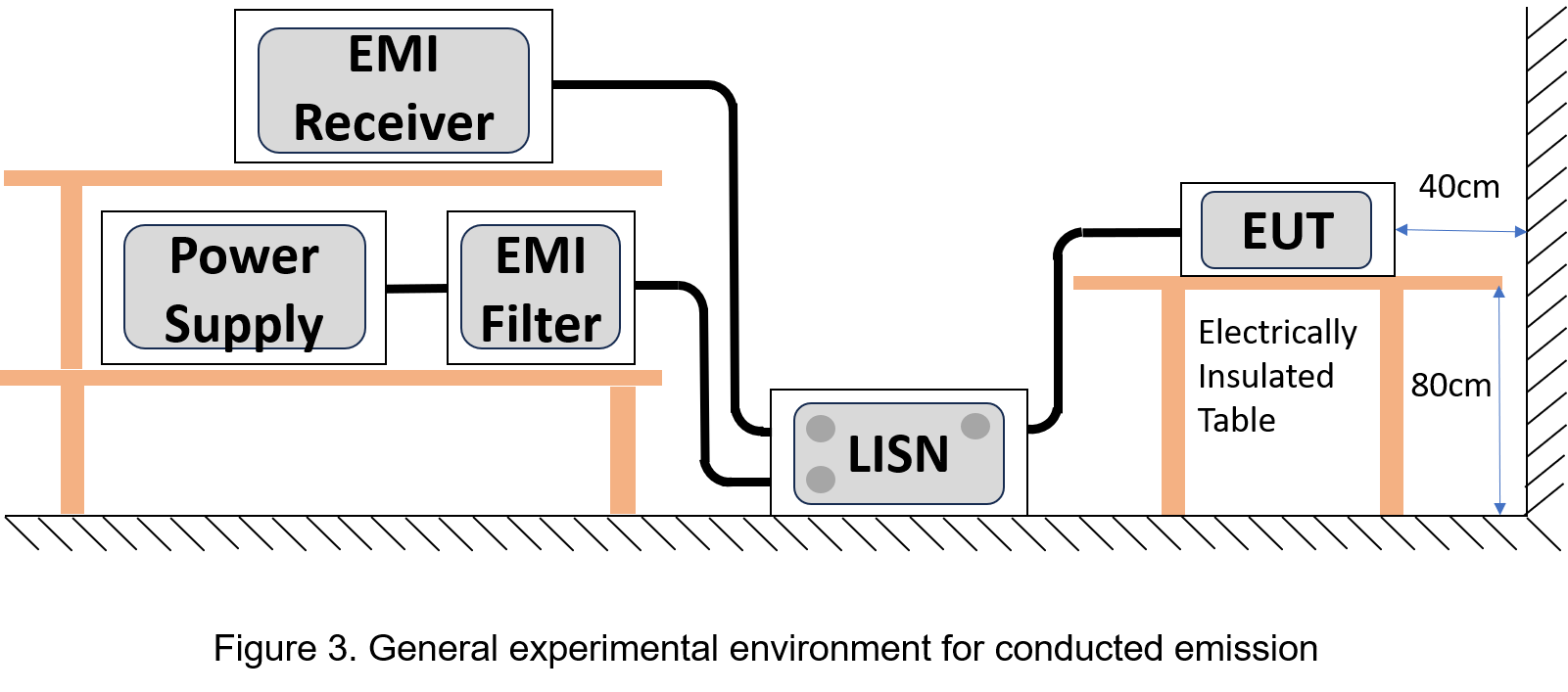

Conducted emissions testing in an environment unwanted noise or electrical interference, it will require preparation of EMI receivers, line impedance stabilization networks (LISNs), EMI filters, power supplies, and power converters. The measurement environment diagram is as follows. The power converter is placed on an electrically insulated table, such as a dry wooden table, and it is more than 40 cm away from the wall and at least 80 cm above the earth ground. The power supply is connected to the input terminal of LISN after passing through the EMI filter, and the output terminal of the LISN is connected to the power supply port of the equipment under test (EUT).

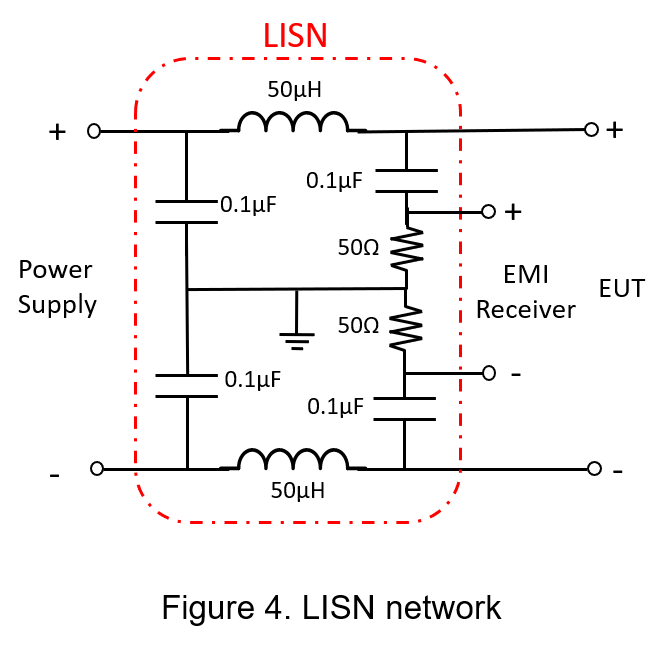

Since the results of conducted emission test will be affected due to different power supply impedances, the function of LISN is to provide accurate impedance for power converters to obtain repeatable EMI test results in all systems, and the results of various international testing agencies are comparable performance while also isolating unwanted RF signals from the power supply. In the frequency range 150kHz-30MHz of conduction test, LISN provides 50ohm matching impedance to the EMI receiver for interference current generated in the power supply of EUT.

EMI receivers have three main detection methods defined by international standards, which are peak, quasi-peak and average,

- Peak detection: Gets the peak value of each harmonic wave, which represents the worst case.

- Quasi-peak detection: Weighted according to the amplitude and repetition frequency of each harmonic wave.

- Average detection: Average value of each harmonic wave in the frequency range.

Application Standards

Many international standards regulate conducted emissions limits to maintain electromagnetic interference. The standards of power converter differ mainly according to the intended use or operating environment of the end product, such as different standards such as medical or automotive applications as well as for different environments such as residential or industrial. The following paragraph will explain more about conducted emission standards for various applications to users, such as standards related to automotive, multimedia and industrial applications.

- EMI Standard for Automotive

Automotive standard for EMI is mainly formulated by the International Special Committee on Radio Interference (CISPR). CISPR is responsible for prescribing and maintaining standards for conducted emissions generated by vehicle components, such as internal combustion engines, and the basic standards are CISPR12 and CISPR25. CISPR 12 is used in supervision and management requirements to ensure that when the internal combustion engine of the vehicle passes by residential or company equipment, the radio of the receiver in the car will not interfere with other electronic equipment and radio reception; CISPR 25 is not a supervision and management standard, which is applicable to the protection of all electronic components in vehicle in the specific frequency band range 150 kHz to 108MHz, which can protect the receiver installed in the same vehicle from interference generated by components/modules.

- EMI Standard for IT and Multimedia

The International Special Committee on Radio Interference (CISPR) has announced that CISPR 32 replaces CISPR 13, including broadcasting equipment field, and CISPR 22, including information technology (IT) field. The European Committee for Electrotechnical Standardization adopted this new standard and published it as EN 55032 as a reference for compliance with electromagnetic compatibility, and then products sold in the EU must meet the requirements of EN 55032.

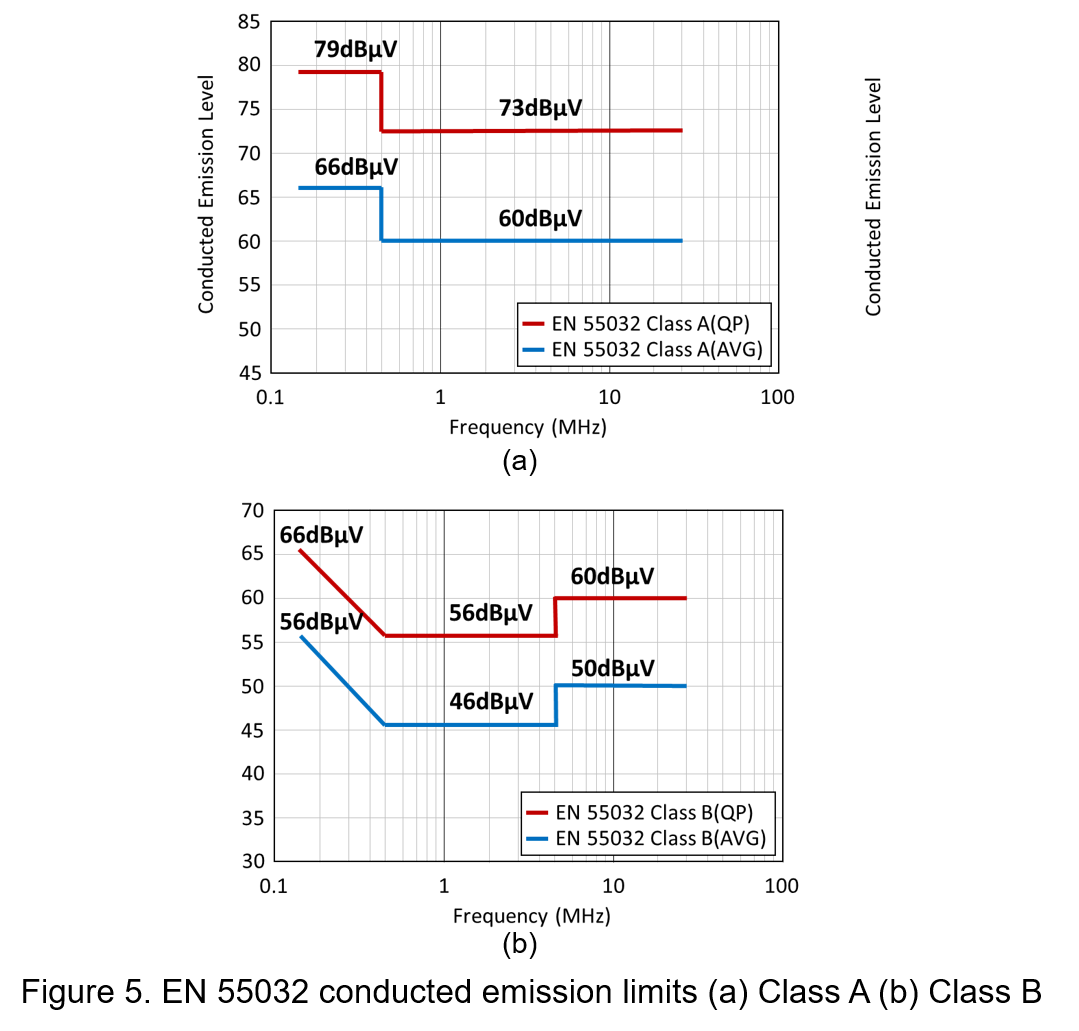

EN 55032 defines whether electromagnetic radiation emitted multimedia equipment with a rated R.M.S supply voltage not exceeding 600 V is acceptable or not. EN 55032 divides two categories according to the environment where the product is used. One is that equipment mainly used in a residential environment must comply with Class B limits; other equipment must comply with Class A limits. The figure below shows the EN 55032 Class A and Class B limits for conducted emissions from quasi-peak and average signal detectors in the frequency range 150kHz to 30MHz.

- EMI Standard for Industrial, Scientific and Medical

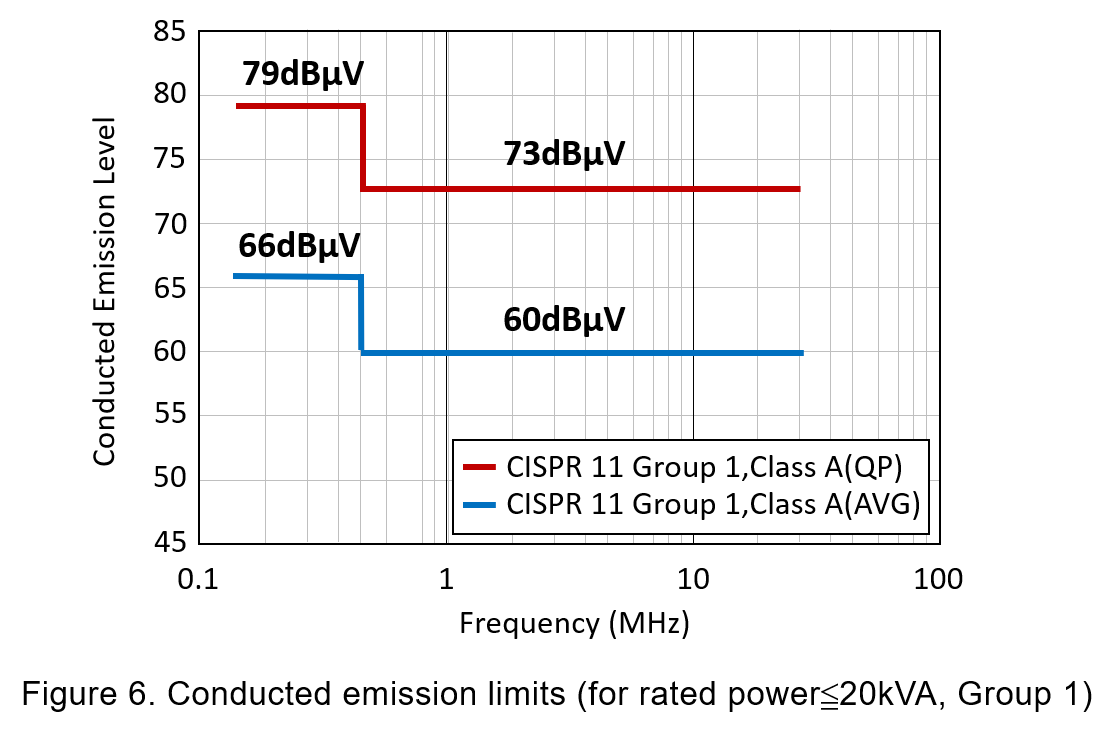

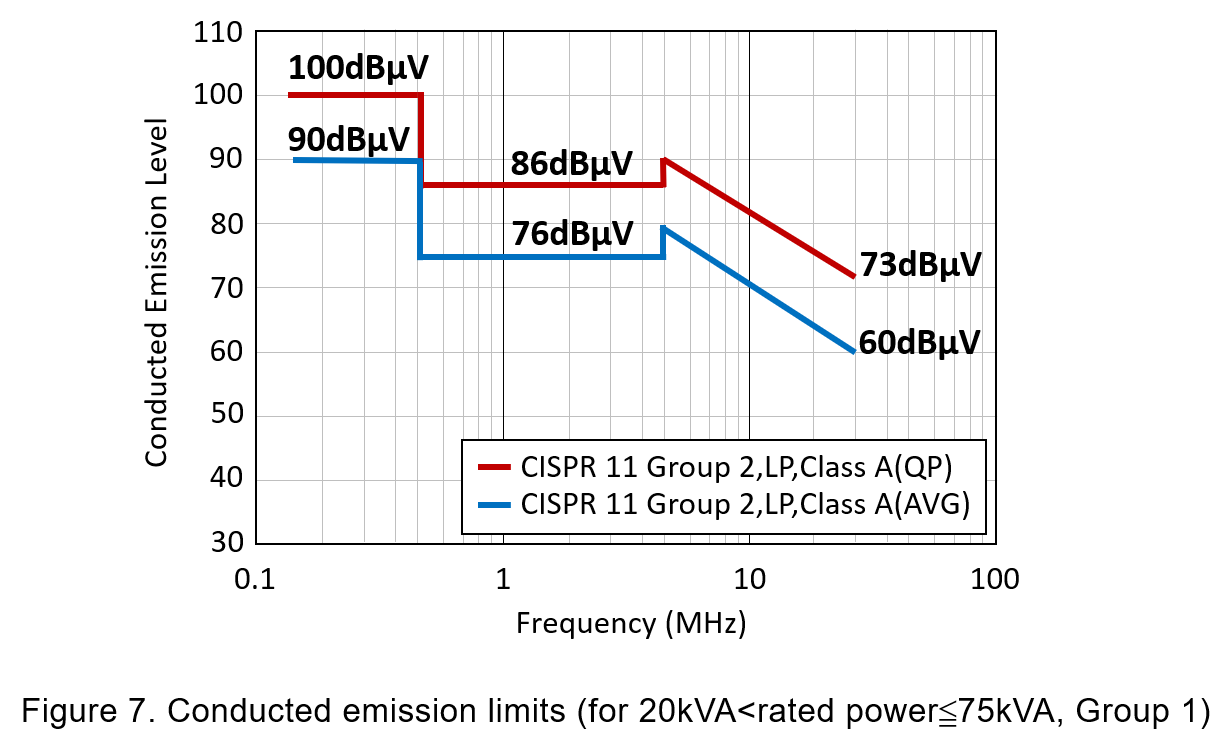

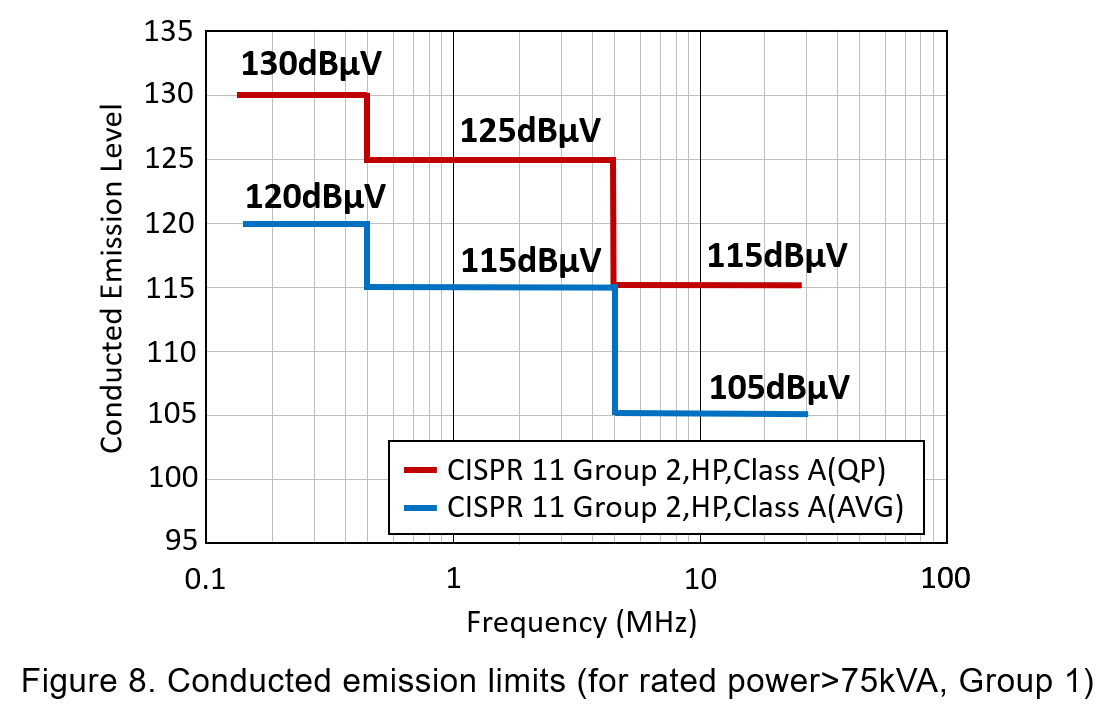

CISPR 11 is the international standard for conducted emissions from industrial, scientific and medical (ISM), which related to radio-frequency (RF) disturbances in the frequency range from 9kHz to 400GHz. CISPR 11 is suitable for a wide variety of equipment, including wireless power transfer (WPT) charging equipment, Wi-Fi systems, microwave ovens, X-ray machines and electronic arc welders. ISM equipment is defined two groups:

(1) Group 1(General application)

Equipment not classified as Group 2, such as laboratory equipment, medical electrical, semiconductor manufacturing equipment or switched mode power supplies, etc.

(2) Group 2(RF-specific application)

Equipment used for inspection, analysis or energy transmission in the form of electromagnetic radiation, inductive and/or capacitive coupling, such as microwave ovens, electric welding equipment or wireless power transfer (WPT) power supplies.

Each group is further subdivided ISM equipment in two classes:

(1) Class A: Equipment is permitted to be installed in all establishments other than domestic and can be measured at the test site or the installation site according to the manufacturer's regulations.

(2) Class B: Equipment suitable for domestic use, also requiring measurements to be made at the test site.

The two classes individually apply different conducted emission limits, and class B is more restrictive than class A.

|

CISPR 11 |

||

|

Group 1 (All ISM, other Group 2) |

Group 2 (ISM with radiated RF) |

|

|

Class A |

Non-intended RF emitter in non-residential region |

Intended RF emitter in non-residential region |

|

Class B |

Non-intended RF emitter in residential region |

Intended RF emitter in residential region |

Summarize the aforementioned international standards, as shown in the table below.

|

Market |

Equipment Type |

Standard |

|

|

IEC/CISPR |

CENELEC/EN |

||

|

ISM |

Industry, Science, Medical |

CISPR 11 |

EN 55011 |

|

Automotive |

Vehicles, ships and engines |

CISPR 12 |

EN 55012 |

|

Electronic Module |

CISPR 25 |

EN 55025 |

|

|

Multimedia |

Broadcast Receivers |

CISPR 32 |

EN 55032 |

|

Information Technology |

|||

|

Audio & Video |

|||

|

Household |

Electrical Equipment |

CISPR 14-1 |

EN 55014-1 |

|

Lighting |

Lamps |

CISPR 15 |

EN 55015 |

Conclusion

Whatever automotive, medical, industrial, or multimedia applications, it is critical for understanding the relevant EMI standards. This article discusses the measurement environment and instruments of conducted emissions, and then lists various regulations and standards for power converter in automotive, IT, multimedia, and industrial applications.

CTC is service provider for high-end power modules (DC to DC Converter and AC to DC Converter) for critical applications worldwide since 1987. We aim to be business generator and a virtual business unit. CTC is your own team with 35 years of experience for a strong business program from market research, product definition & development, supply chain management and total technical services.

CTC is the only corporation certificated with ISO-9001, IATF-16949, ISO22613(IRIS, AFNOR silver certificate), and ESD/ANSI-2020. We can 100% ensure not only the product, but also our workflow and service to match quality management system for every high-end application from the very beginning. From design to manufacturing and technical support, every single detail is operated under highest standard.