You are here

Back to topNotices for Trimming the Output Voltage

The applications of power converters include energy storage devices, electric vehicles, railways, and Industry 4.0, etc., the operating conditions and voltage requirements of power converters are also different. This article describes the reasons for adjusting the output voltage, how to use an external circuit to adjust the output voltage, and what limitations the adjustment range will have.

Introduction

The output voltage may not be stable in a serious environment or improper operation. The challenges are how wide the output voltage varies, whether it causes damage to the components, and how the output voltage value can meet any application. Therefore, trimming the output voltage of the power converter is necessary.

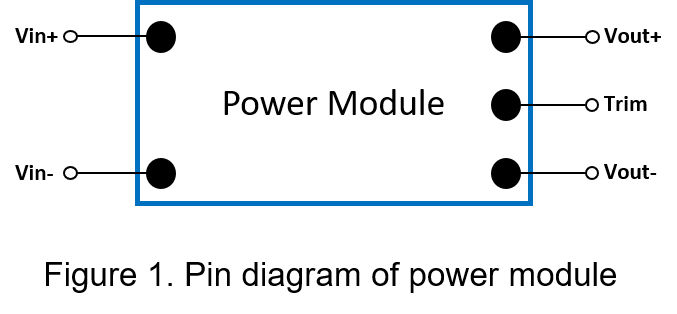

In general, the power converter has the specified output voltage value, and the Trim pin of Figure 1 allows the user can freely adjust the output voltage within the range of ±10% or less.

Providing a simple way for the user to meet the needs of the system power supply by adding external resistors, and the following will introduce the trimming methods and restrictions.

Reasons for Trimming the Output Voltage

Trimming output voltage of the power converter are mostly due to the following three reasons:

- Different Applications and Environments

For wind power generation systems, the output voltage and frequency of power converter inside the generator will be changed with different wind speeds; for Industry 4.0, sensors require high-accuracy supply voltages, so users can trim the output voltage level for different applications.

- The Influence of Back-end Circuit

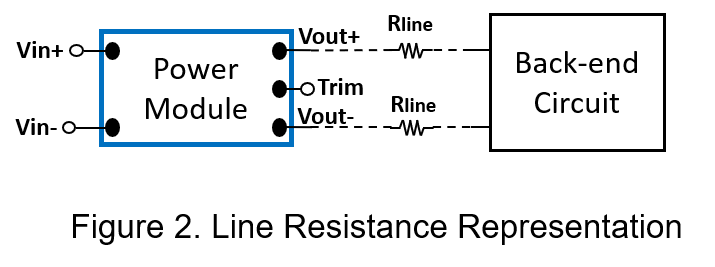

Even if operating in same application, load of the power converters may be different. For example, the voltage drop caused by the long wire distance between the output pin of the power converter and the back-end circuit, causing excessive line-resistance. Finally, it affects the overall efficiency of system. Therefore, directly fine-tuning the output voltage can overcome the loss caused by the wire or the connection point, as shown in Figure 2.

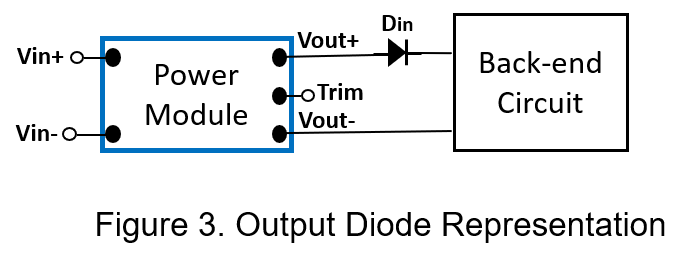

In another case, adding a diode in the power converter output to prevent the reverse current from the back-end circuit, so the output voltage needs to be increased the forward bias of a diode, 0.3 to 0.7 volts , to maintain the performance of system.

- Diversified Output Voltage

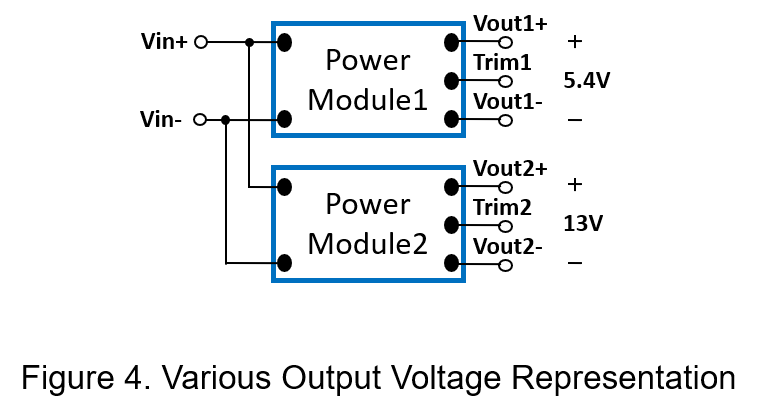

Another case is that the application requires a variety of output voltages, and the application requirements are not standard output voltages, for example, output voltages of two power modules in Figure 4 are 5.4V and 13V, which are not common voltage, 5V and 12V. Therefore, it is most efficient to directly change the power converter to obtain the desired output voltage.

How to Trim the Output Voltage

Introduce a method of fine-tuning the output voltage, which is by changing the value of the impedance components in the feedback network, that is, adjusting the scale factor of the feedback network. The power converter adds a trim pin (Trim) to the feedback node. When the load current changes from light load to heavy load or the input voltage changes from low voltage to high voltage, the user can add a high-impedance resistor between Trim pin and Vout pin to achieve output voltage adjustment range of ±10%.

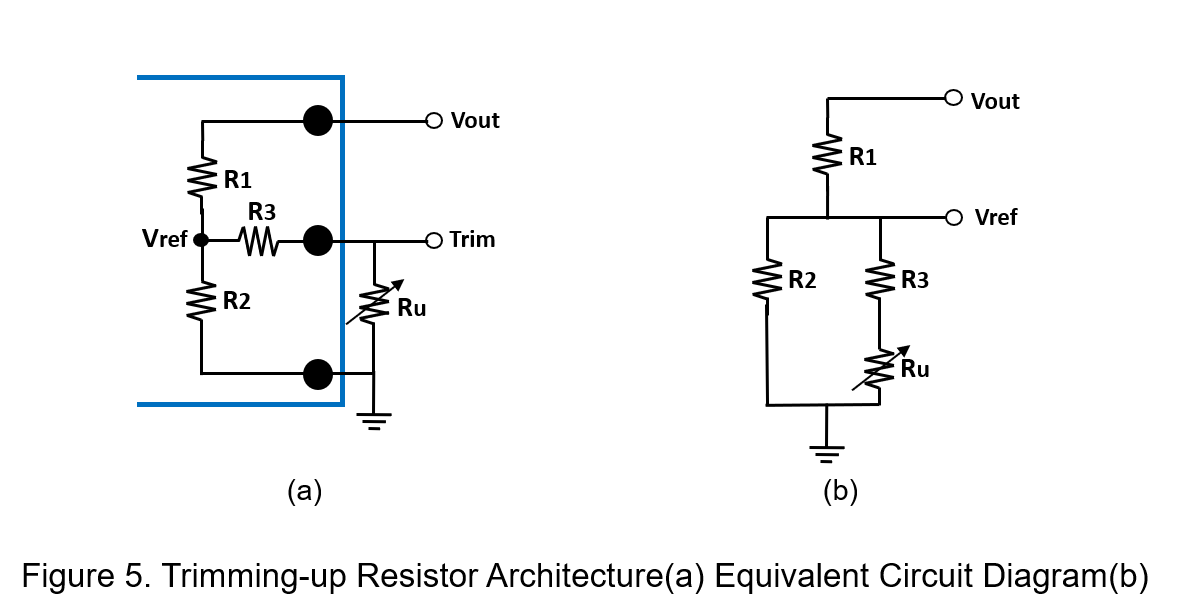

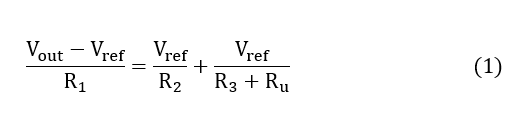

Assume that the negative output pin (Vout-) is connected to ground, and trimming-up resistor (Ru) is added to both ends of the negative output pin and the trim pin, as shown in Figure 5.

According to Kirchhoff's circuit law, the relationship between the output voltage and each resistance can be derived:

The result is calculated by the operation:

When knowing the desired trimming-up output voltage, internal resistances R1-R3 and the reference voltage Vref, the external resistor (Ru) is deduced through equation (2).

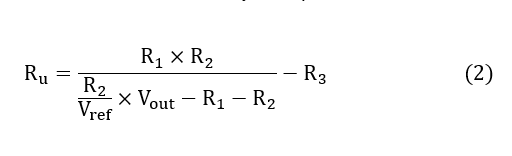

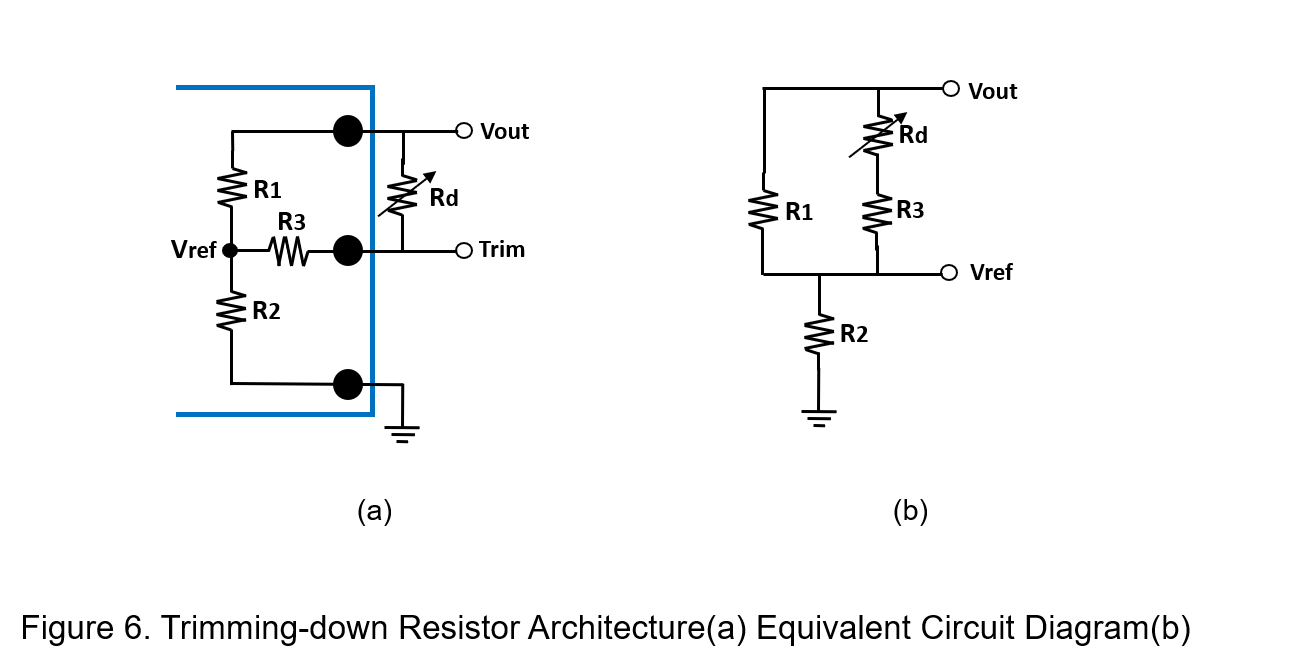

In addition, if trimming-down resistor (Rd) is applied to both the positive output pin and the trim pin, as shown in Figure 6.

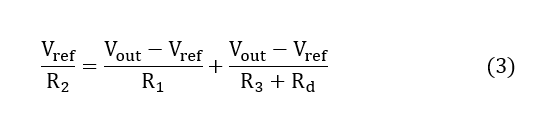

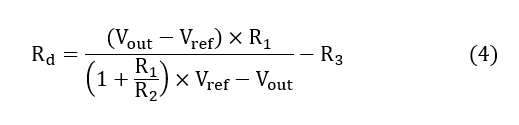

According to Kirchhoff's circuit law, the relationship between the output voltage and each resistance can be derived:

The result is calculated by the operation:

When knowing the desired trimming-down output voltage, internal resistances R1-R3 and the reference voltage Vref, the external resistor (Rd) is deduced through equation (4).

Trimming Limits of Output Voltage

For power converters with trimming function, adding resistors can be used to adjust the output voltage in a fixed range, which is general ±10%. Once the user adjusts the output voltage more than ±10%, it will inevitably affect the performance of system. Common limiting factors for Trimming include

(1) Duty Cycle Range

The control loop design limits the minimum and maximum duty cycle. Once the output voltage changes beyond expectation value, the control loop cannot provide a proper duty cycle to stable output voltage within the specification range.

If both external resistor and the output voltage continue to exceed specification range, the feedback factor and dc gain of the closed loop are affected, respectively. In result, it causes to provide a poor frequency response and even lead the system to oscillate.

(2) Withstand Voltage of Component

The maximum cross-voltage of the power switching elements is affected by the output voltage. For flyback converter, the withstand voltage of primary-side power switching element must be greater than the maximum of drain-source voltage, and the drain-source voltage is:

Vin: input voltage; Vout: output voltage; n: turns ratio of primary side to secondary side

Therefore, the cross-voltage of power switching element will change proportionally with the output voltage, so the maximum of the output voltage is used to select the withstand voltage of the power element.

Measurement Results

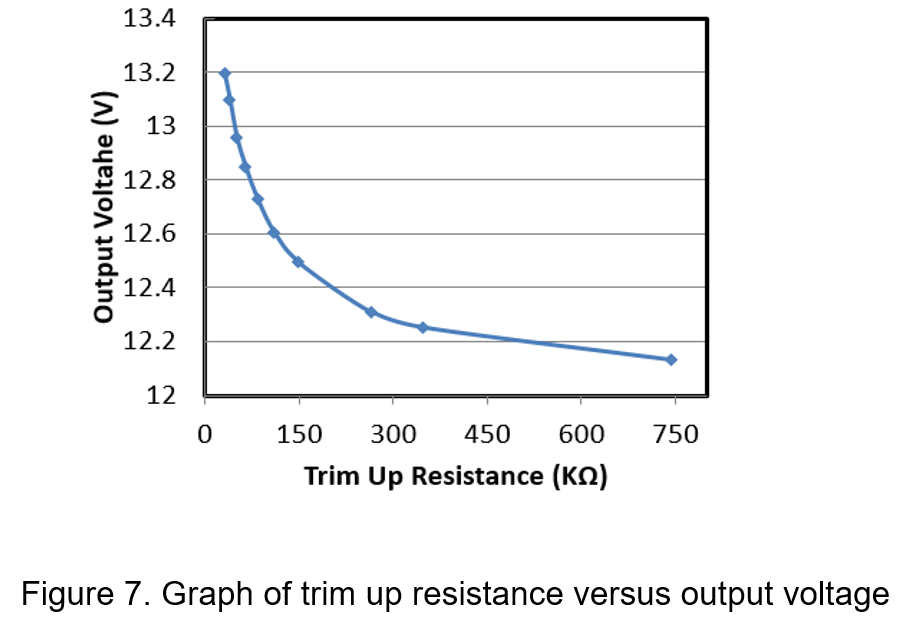

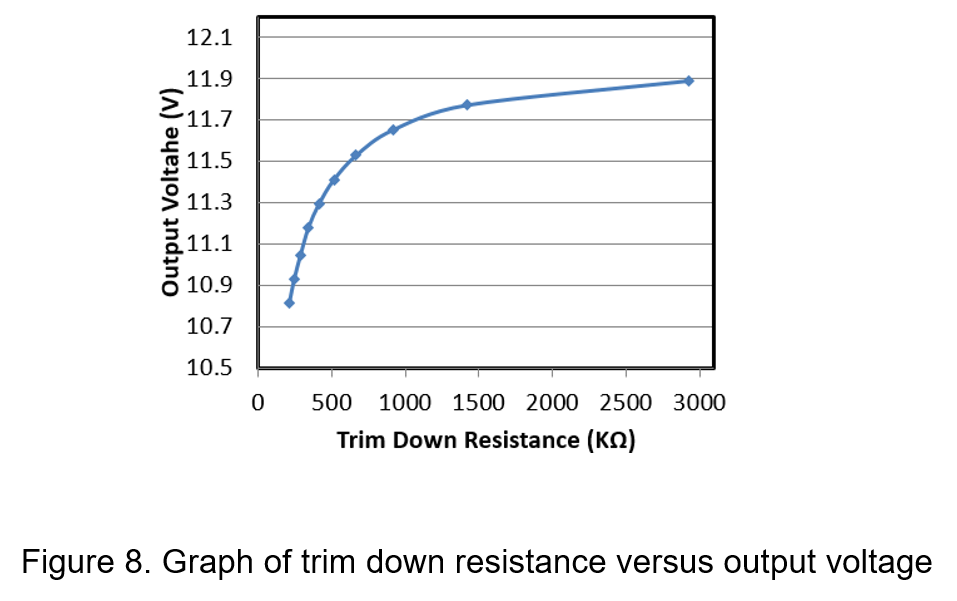

Confirm the relationship between the output voltage range and external resistance of flyback converter. The specifications of the flyback converter are input voltage 48Vdc, un-trimmed stable output voltage 12Vdc, and the load current is fixed at 2A, and make detailed records output voltage, duty cycle, and external resistor when trimming every 1% increase or decrease.

When output voltage is actually measured from +1% to +10%, the trimming-up resistance value is expressed as the horizontal axis and the output voltage is expressed in the vertical axis.

When output voltage is actually measured from -1% to -10%, the trimming-down resistance value is expressed as the horizontal axis and the output voltage is expressed in the vertical axis.

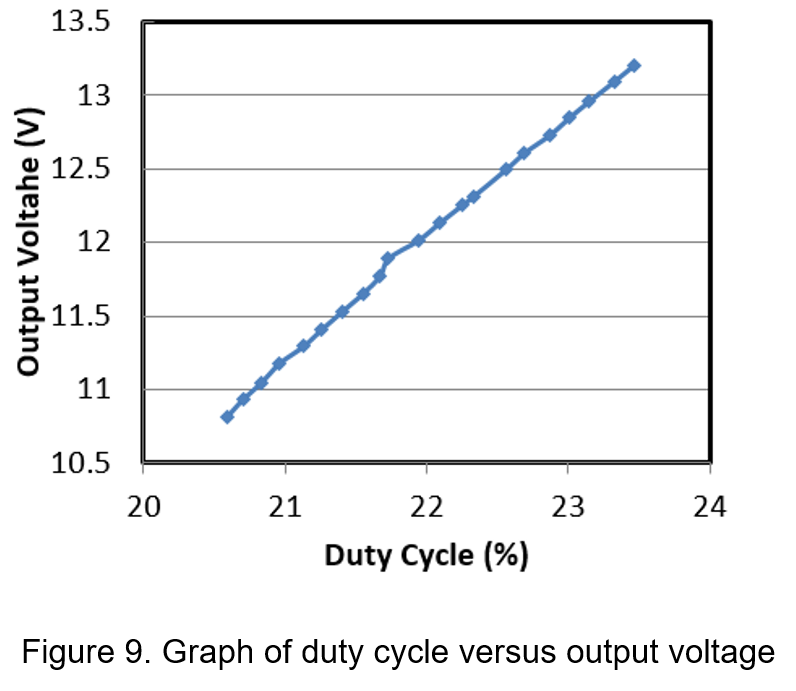

In addition, when the output voltage is implemented from -10% to +10%, observe the range of the duty cycle. From the experimental results, it is known that changing the Trimming resistor not only obtains the desired output voltage, but also has better linearity in the variation of the duty cycle. In the result, the output voltage can range from -10% to +10% by changing the duty cycle by as little as 2.8%.

Conclusion

The function to trim output voltage offers advantages in many applications, but is also limited by duty cycle, component withstand voltage, and system stability. Select the appropriate external resistor through the trimming equation to ensure normal operation of the power converter.

CTC is service provider for high-end power modules (DC to DC Converter and AC to DC Converter) for critical applications worldwide since 1987. We aim to be business generator and a virtual business unit. CTC is your own team with 35 years of experience for a strong business program from market research, product definition & development, supply chain management and total technical services.

CTC is the only corporation certificated with ISO-9001, IATF-16949, ISO/TS22613 (only company in Taiwan with Silver Performance Level) and ESD/ANSI-2020. We are specialized for critical and higher-end applications, such as Industrial, Railway, E-mobility, Medical etc. Our technical competences are ultra-wide input voltage up to 12:1, wide Operating temperature from -40°C to 110°C, high insulation level up to reinforced and 2MOPP, high isolation level up to 20KV DC/ min, specific EMC solutions with EMI Class A Built in. Besides, CTC began implementing Smart Manufacturing to achieve dynamic deliveries with globalized production sites.

CTC powering your core !